Why are Aircom piping systems Energy Saving systems?

Compressed air is the most expensive energy in a factory and a piping system with extruded aluminium pipes and high-quality fittings provides a significant contribution to reducing energy consumption – this is a fact, but WHY?

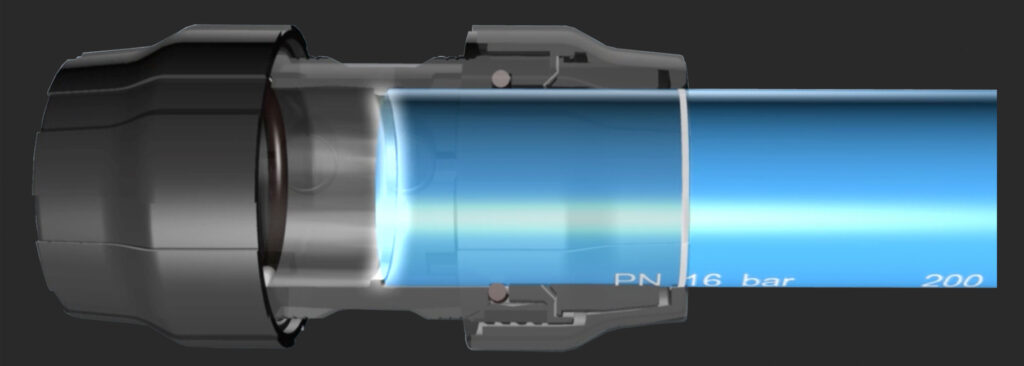

First of all, the particularly smooth internal surface of Aircom pipes allows for turbulence-free air flows.

In addition, all Aircom fittings are full bore and therefore allow complete air flow, without bottlenecks or unnecessary pressure drops, and without causing further turbulence in the air flow.

The construction and assembly technology of Aircom fittings eliminates air leakages and consequently makes an air distribution system made with Aircom pipings extremely efficient.

These simple factors mean that the air compressor runs much less and consequently consumes less electricity while also limiting CO2 emissions.

A machine that works less needs less maintenance – and we all know that compressor maintenance is a significant cost.

Having an efficient compressed air distribution system is like having an extra compressor in the company!